Formation of the Great North Road

Excavation, Filling & Embankment

A selection of methods used

in construction of the Great

North Road

A selection of methods used

in construction of the Great

North Road

Today we can view the layout of the countryside below us from a helicopter or an aeroplane, fitted with specialised cameras, to make a record of the problems we face in construction projects. The Surveyor-General of the 1820s and his staff of Assistant Surveyors could only view the mountains, steep slopes, rocky cliffs, gullies, hollows, valleys and creeks by getting up on the highest ground around, as Mitchell did, to study and sketch possible routes. The alternative was just to tramp their way through the undergrowth and trees, making appropriate notes and using dead reckoning methods for the definition of the route.

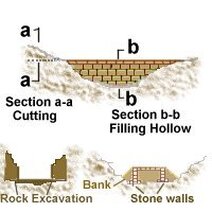

Even with their cleared and surveyed path, its irregularities had to be overcome. They had to decide on methods for cutting around any steep slope, blasting away underlying rock, to make a road with a gradient that could be used by the vehicles of the time. That might entail embankment on one side of the cutting or even a massive rock structure to prevent slippage. It could mean embankment on both sides of the road over a hollow. In crossing a gully, hollow or valley, a raised structure could be required with suitable embankment supporting the road surface. In a gully with a creek running through it, the decision could be a bridge structure at a height to allow for flood conditions. Cutting, filling, embanking, bridging were all to be considered and that was a slow process, always bearing in mind the essential requirement for good drainage methods to prevent road washaways. In spite of the regularity of droughts, there were those times when it must have seemed that the prehistory Deluge had started again. The Assistant Surveyors were faced with the need to make decisions on any of these types of structure, with difficult restraints confronting them. Reference has already been made to some of these structures that were required.

Assistant Surveyor Percy Simpson reported in January 1830 that part of a Gang had been occupied in filling an extensive Hollow near 7 Mile Post and building side walls therein.. Part of No.25 Road Party have been employed excavating an approach (from the side of the Mountain) to the Bridge on the Line of Road running parallel to the North Shore of the River [Hawkesbury], widening the Road in places where required leading to the Bridge and side cutting and quarrying beyond and northward of the same. Others of the Party have been employed digging a Foundation for a side wall and in blasting and removing some extensive overhanging Rocks wherefrom the requisite width of the Road must be taken. Month in, month out, similar structures were put in place making the Great North Road, often in severe conditions of temperature, weather and land with ridges, cliffs, valleys, hollows, water courses and tough sandstone rock everywhere.

Even with their cleared and surveyed path, its irregularities had to be overcome. They had to decide on methods for cutting around any steep slope, blasting away underlying rock, to make a road with a gradient that could be used by the vehicles of the time. That might entail embankment on one side of the cutting or even a massive rock structure to prevent slippage. It could mean embankment on both sides of the road over a hollow. In crossing a gully, hollow or valley, a raised structure could be required with suitable embankment supporting the road surface. In a gully with a creek running through it, the decision could be a bridge structure at a height to allow for flood conditions. Cutting, filling, embanking, bridging were all to be considered and that was a slow process, always bearing in mind the essential requirement for good drainage methods to prevent road washaways. In spite of the regularity of droughts, there were those times when it must have seemed that the prehistory Deluge had started again. The Assistant Surveyors were faced with the need to make decisions on any of these types of structure, with difficult restraints confronting them. Reference has already been made to some of these structures that were required.

Assistant Surveyor Percy Simpson reported in January 1830 that part of a Gang had been occupied in filling an extensive Hollow near 7 Mile Post and building side walls therein.. Part of No.25 Road Party have been employed excavating an approach (from the side of the Mountain) to the Bridge on the Line of Road running parallel to the North Shore of the River [Hawkesbury], widening the Road in places where required leading to the Bridge and side cutting and quarrying beyond and northward of the same. Others of the Party have been employed digging a Foundation for a side wall and in blasting and removing some extensive overhanging Rocks wherefrom the requisite width of the Road must be taken. Month in, month out, similar structures were put in place making the Great North Road, often in severe conditions of temperature, weather and land with ridges, cliffs, valleys, hollows, water courses and tough sandstone rock everywhere.

Hand Drilling and Black Powder Blasting

Hand Drilling

The work is either “single-hand” or “double-hand”. In single-hand drilling, the operator wields the hammer with one hand and with the other holds the drill or bit, rotating it slightly after every blow in order to keep the hole round and prevent the drill from wedging fast. In double-hand work (two-man team), one man strikes, while the other holds and rotates the drill. (This quote and the following text is from Ref.1.) A drill is a steel bar, generally octagonal in cross-section, one end of which is forged out to a cutting edge. The edge of the drill is made either straight like that of a chisel, or with a convex curve, this shape being better for very hard rock. For hard rock the cutting edge should be rather thicker and blunter and therefore stronger than for soft rock. The diameter of the drill is usually from 3/4 to 1 inch and the length of the cutting edge (or gauge) of the drill is always greater than the shank diameter, the proportion varying from 7:4 to 4:3.

Holes of more than 10 to 12 inches deep generally require the use of a set of drills of different lengths and depending in number on the depth required. The shortest drill for starting the hole has the widest cutting edge, the edges of the others being successively narrower and graduated to follow each other properly, as drill after drill is dulled in deepening the hole. Thus the hole decreases in diameter as it is made deeper.

If the hole is directed downward, a little water is poured into it at intervals to keep the cutting edge of the drill cool and make a thin mud of the cuttings. From time to time, the hole is cleaned out by the scraper or spoon, a long slender iron bar forged into the shape of a hollow cylinder with one end flattened over and turned at right angles.

The jumper is a long steel bar, with the cutting edge as described, and is raised alternatively and dropped in the hole by one or two men. In rock work, this technique is used on occasions for near vertical holes of some length but it is usual for the hammer to be used on the bar, especially in hard rock. For hard rock, double-hand drilling is preferable and may even be essential to secure a reasonable speed of work. Holes drilled by hand usually vary in depth from 18 to 36 inches according to the nature of the rock and the purpose of the work though deeper holes may be made.

Holes of more than 10 to 12 inches deep generally require the use of a set of drills of different lengths and depending in number on the depth required. The shortest drill for starting the hole has the widest cutting edge, the edges of the others being successively narrower and graduated to follow each other properly, as drill after drill is dulled in deepening the hole. Thus the hole decreases in diameter as it is made deeper.

If the hole is directed downward, a little water is poured into it at intervals to keep the cutting edge of the drill cool and make a thin mud of the cuttings. From time to time, the hole is cleaned out by the scraper or spoon, a long slender iron bar forged into the shape of a hollow cylinder with one end flattened over and turned at right angles.

The jumper is a long steel bar, with the cutting edge as described, and is raised alternatively and dropped in the hole by one or two men. In rock work, this technique is used on occasions for near vertical holes of some length but it is usual for the hammer to be used on the bar, especially in hard rock. For hard rock, double-hand drilling is preferable and may even be essential to secure a reasonable speed of work. Holes drilled by hand usually vary in depth from 18 to 36 inches according to the nature of the rock and the purpose of the work though deeper holes may be made.

A Side-line Story

Great North Road Convict Road GangThere is the following quotation of interest on the subject of hand drilling, “In hard ground, in the days before machine drilling, a two-man team – one wielding the hammer and another turning the borer – might take 3 hours or more to drive a hole twenty inches deep, using a dozen or more steels . With the quality of metal then available a borer might last twenty minutes at most before it became too dulled for further use and had to be set aside to be re-forged.” The footnote quantifies the qualities shown by some two-man teams: “The exceptional speeds, attained in hand boring contests held from time to time, bore no relation to normal work underground. In one such contest attended by 1,000 people in August 1888, five teams competed and a Tincroft ‘pare’ (i.e. a group of miners who worked together) bored 13″ in hard granite in under seven minutes, at a striking rate (with hammers slung full round) at 91 per minute.”

It is unlikely that convict pairs would reach such speeds though the sandstone rock, would it does not rival the hardness of granite, even if it included the red ironstone in the body of the rock.

It is unlikely that convict pairs would reach such speeds though the sandstone rock, would it does not rival the hardness of granite, even if it included the red ironstone in the body of the rock.

Blasting with Black Powder

Until 1864, gunpowder (black powder) was the only available explosive but, in that year, Alfred Nobel first used nitroglycerin for blasting. Gunpowder is seldom used for rock blasting today, except in quarrying building stone, where a slow explosive of relatively low power is desirable to avoid shattering the stone. Black powder is exploded by deflagration, by means of a fuse, and exerts a comparatively slow and rending force.

The powder is coarse-grained, usually from 1/8″ to 3/16″ in particle size and is charged in paper cartridges 6 to 10 inches long and of proper diameter to fit loosely in the drill hole. A piece of fuse, long enough to reach beyond the mouth of the hole, is inserted in the cartridge and tied fast. For wet holes paraffined paper is used, the miner waterproofing joints with grease. When more than one cartridge is required for the blast, that which has the fuse attached is usually charged last. The cartridges are carefully rammed down by a wooden tamping bar and the remainder of the hole is filled with tamping consisting of finely broken rock, clay or other comminuted material carefully compacted by the tamping bar on top of the charge. The fuse is a cord having in the centre a core of gunpowder enclosed in several layers of linen or hemp waterproofed covering. When ignited, the fuse burns down at a rate of approximately three feet per minute, the fuse-lighter using a sufficient length of fuse to allow him to reach a place of safety.

For breaking coal in gassy mines and in some stone works, several substitutes for explosives have been used to a limited extent. Examples are:

• Plugs of wood driven tightly into a row of drill holes which, once wetted, swell and

split the coal or rock;

• Quicklime cartridges which expand powerfully on the application of water; and

• Simple wedges driven by hammer into drill holes.

In the Excavation and Embankment section, we mentioned the work on the road running west along the north side of the River Hawkesbury from the ferry to the start of the incline up Devine’s Hill section of the road. Both of these operations were under the supervision of Percy Simpson and both required rock to be removed by drilling and blasting to provide the basic width for a roadway. The roadway along the riverside would have been a relatively straightforward task compared with the work which lasted nearly three years in getting the Great North Road up the Devine’s Hill Ascent. It is interesting to contemplate the enormity of the work which was undertaken by the road gangs carrying out all the activities involved. The final result was a magnificent piece of road construction.

The powder is coarse-grained, usually from 1/8″ to 3/16″ in particle size and is charged in paper cartridges 6 to 10 inches long and of proper diameter to fit loosely in the drill hole. A piece of fuse, long enough to reach beyond the mouth of the hole, is inserted in the cartridge and tied fast. For wet holes paraffined paper is used, the miner waterproofing joints with grease. When more than one cartridge is required for the blast, that which has the fuse attached is usually charged last. The cartridges are carefully rammed down by a wooden tamping bar and the remainder of the hole is filled with tamping consisting of finely broken rock, clay or other comminuted material carefully compacted by the tamping bar on top of the charge. The fuse is a cord having in the centre a core of gunpowder enclosed in several layers of linen or hemp waterproofed covering. When ignited, the fuse burns down at a rate of approximately three feet per minute, the fuse-lighter using a sufficient length of fuse to allow him to reach a place of safety.

For breaking coal in gassy mines and in some stone works, several substitutes for explosives have been used to a limited extent. Examples are:

• Plugs of wood driven tightly into a row of drill holes which, once wetted, swell and

split the coal or rock;

• Quicklime cartridges which expand powerfully on the application of water; and

• Simple wedges driven by hammer into drill holes.

In the Excavation and Embankment section, we mentioned the work on the road running west along the north side of the River Hawkesbury from the ferry to the start of the incline up Devine’s Hill section of the road. Both of these operations were under the supervision of Percy Simpson and both required rock to be removed by drilling and blasting to provide the basic width for a roadway. The roadway along the riverside would have been a relatively straightforward task compared with the work which lasted nearly three years in getting the Great North Road up the Devine’s Hill Ascent. It is interesting to contemplate the enormity of the work which was undertaken by the road gangs carrying out all the activities involved. The final result was a magnificent piece of road construction.

The Theoretical Process

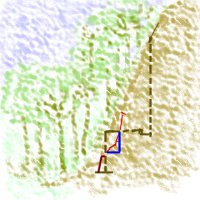

Diagram showing the

intended work on the

hill side to build the road.

Diagram showing the

intended work on the

hill side to build the road.

Let us consider a hypothetical operation for a new ascent; but, remember, it is hypothetical and may not represent the truth of the past! Governor Darling and Surveyor General Mitchell are visiting the Finch Ascent with the Assistant Surveyor Heneage Finch. Clearing and road construction with drilling and blasting has proceeded to the extent that access is possible almost to the ridge where the ground levels off somewhat. Governor Darling objects to the tight zig-zag corners on the way up and turns to Mitchell to say, “I do not like the narrow corners. Large ox-drawn wagons will not make it around these tight bends and there is no place to rest them. Find another route and do it yourself!”

Finch searches for some other routes and they are not acceptable to Mitchell who decides that he had better take the task on himself, as directed. On the other western side of the ridge is a valley. The eastern side of this valley is rising rather formidably up to over 100 feet to the ridge line above. On investigation, he finds a way up the valley can be found to meet up with Finch’s Ascent at around 550 feet above sea-level. After a lengthy investigation, he decides that it should be possible to make a road with a very reasonable gradient up to about the 100 metre (300 ft.) contour level. From there, it would be necessary to weave around some corners to follow the ridges and to join with the Finch Ascent road at just over the 160 metre (540 ft) contour level. It will involve cutting away rock to make a road that is wide enough , probably with some support structures. Meanwhile Percy Simpson has taken over the work on both sides of the River Hawkesbury and Mitchell instructs him to stop work on the Finch Ascent road and transfer road gangs to other side of the ridge on Molly Devine’s property.

Simpson arranges to clear away trees and undergrowth on the preferred line. He looks at the slope, tests the ground cover and decides that there will have to be some heavy rock removal by blasting to provide, first of all, the footings for the workers, and secondly, the rock ledge that will take the roadway and the necessary drain near the vertical rock wall (the brown dotted lines in the drawing). That will mean retaining walls and embankment may be essential. Drilling begins working back to get some footing for the drillers and an escape route when the blasting is under way. They get the rock to a level that looks to be correct when the valley edge of the rock collapses away down the slope (the red sloping line near the outer edge). He had observed that there were major break lines, near horizontally, but had not expected a crack of a vertical nature. The rock is cleared away and a squared off section is set back below the anticipated road level. A retaining wall is built there to give some access up the hill, set back from the main road width where the main retaining wall is being built. This new walling will provide a stabilising influence on the main wall (the blue lines). The work now continues up Devine’s Hill, using the same principles as the double wall, as necessary. It is slow and much gunpowder is required for the blasting. However, the jumpbar drilling can continue apace, irrespective of the availability of the gunpowder supply. And so it goes on and we end here with this hypothetically suppose operation to return to what is historically known.

Finch searches for some other routes and they are not acceptable to Mitchell who decides that he had better take the task on himself, as directed. On the other western side of the ridge is a valley. The eastern side of this valley is rising rather formidably up to over 100 feet to the ridge line above. On investigation, he finds a way up the valley can be found to meet up with Finch’s Ascent at around 550 feet above sea-level. After a lengthy investigation, he decides that it should be possible to make a road with a very reasonable gradient up to about the 100 metre (300 ft.) contour level. From there, it would be necessary to weave around some corners to follow the ridges and to join with the Finch Ascent road at just over the 160 metre (540 ft) contour level. It will involve cutting away rock to make a road that is wide enough , probably with some support structures. Meanwhile Percy Simpson has taken over the work on both sides of the River Hawkesbury and Mitchell instructs him to stop work on the Finch Ascent road and transfer road gangs to other side of the ridge on Molly Devine’s property.

Simpson arranges to clear away trees and undergrowth on the preferred line. He looks at the slope, tests the ground cover and decides that there will have to be some heavy rock removal by blasting to provide, first of all, the footings for the workers, and secondly, the rock ledge that will take the roadway and the necessary drain near the vertical rock wall (the brown dotted lines in the drawing). That will mean retaining walls and embankment may be essential. Drilling begins working back to get some footing for the drillers and an escape route when the blasting is under way. They get the rock to a level that looks to be correct when the valley edge of the rock collapses away down the slope (the red sloping line near the outer edge). He had observed that there were major break lines, near horizontally, but had not expected a crack of a vertical nature. The rock is cleared away and a squared off section is set back below the anticipated road level. A retaining wall is built there to give some access up the hill, set back from the main road width where the main retaining wall is being built. This new walling will provide a stabilising influence on the main wall (the blue lines). The work now continues up Devine’s Hill, using the same principles as the double wall, as necessary. It is slow and much gunpowder is required for the blasting. However, the jumpbar drilling can continue apace, irrespective of the availability of the gunpowder supply. And so it goes on and we end here with this hypothetically suppose operation to return to what is historically known.

The Real Process

The actual route that was taken for the Devine’s Hill Ascent up to the junction with the Finch Ascent is shown in the map section. The roadway from the original Wiseman’s Ferry Crossing comes in at the bottom of the map image passing the present day ferry crossing, going over the bridge (green marking) which Simpson and his Road Gangs constructed, up to the point where it goes north up Devine’s Hill (bracketted in green). The junction with the Finch Ascent is at the top, right hand side of the map.The yellow bars across the road mark the contour levels in metres, on the way up the road. It is very evident, from these contour levels and the spacing along the road, that Mitchell had judged the route well and that Simpson, with time and much effort from his gangs, was able to make a fine access road up the hill and onto the ridge above. The slope of the drop from the ridge down into the valley was steep and, under the small amount of soil bound together by the roots of tree and the undergrowth, lay solid sandstone rock. From the picture of the present-day wall of rock, it is possible to recognise the enormous amount of work which was done by hand drilling, blasting and moving rock.

Near the white patch of recessed rock the half drill-holes can be seen in two places, about one metre in length. Further up the wall of rock above the top of this picture, there are further halves of drill holes, left after the blast had removed the rock, taking with it the other halves of the drill hole. Near the bottom of the picture, there is a dark fracture in the rock running at 45 degrees to the vertical. Such rock fractures must have been a problem which could have occurred anywhere along the chosen route. Recovery of a suitable rock surface could have been the reason for the double walling which seems to have shown up when one of the buttresses of the major Devine’s Hill walling collapsed in the early 20th Century. Alternatively, it may have been a preliminary walling to give a narrower access up the hill while the main road work continued.

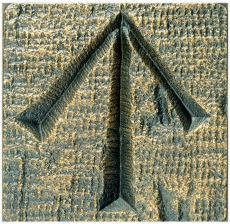

The remains of holes, such as this one made by hand drilling with a jumperbar, can be seen in many places up Devine’s Hill and along the rest of the Great North Road as it progressed north past Mount Manning to Wollombi. It lives on as a sculptured reminder of the immense effort which was expended by many men in convict clothing during the Great North Road construction.

The remains of holes, such as this one made by hand drilling with a jumperbar, can be seen in many places up Devine’s Hill and along the rest of the Great North Road as it progressed north past Mount Manning to Wollombi. It lives on as a sculptured reminder of the immense effort which was expended by many men in convict clothing during the Great North Road construction.

Building Bridges for the Great North Road

The surviving masonry bridges constructed on the Great North Road are the oldest known on the Australian mainland and constitute an excellent collection of evidence about bridge-building in NSW before the appointment of the first scientific bridge builder, David Lennox, in 1832, whose work is well-documented by Newell (1938). Each bridge of this pre-1832 period is different in scale and construction, but they are all stone conduit bridges which would have had timber decks built from girders and slabs. This comment was made by Dr Grace Karskens in the CTP Monograph Four Essays about the Great North Road

The Convict Trail Project Conservation Management Plan (Stage 1)

It is repeated in the CTP Conservation Management Plan, produced for The Convict Trail Project by Siobhan Lavelle, Historical Archaeologist & Heritage Consultant, in association with Dr Grace Karskens and RTA Technology. We introduce it here because it gives the opportunity to provide background on the extent of the operations of the Convict Trail Project on the historic background and heritage significance of the Great North Road, particularly in relation to the construction of bridges. Use will be made of the Section and Precinct Description Sheets which accompany the Conservation Management Plan Document. If you wish to read the Conservation Plan Report in detail and even download it, you should go to the Business Plan Icon on the CTP Homepage. That will take you in steps to the Plan Report, to maps of the whole area and other interesting material. The investigations for the Plan were divided into eight separate primary Inventory Sections and these were further subdivided into 39 Precincts. The reason for these divisions is that the existing line or corridor of the Great North Road, being such a lengthy heritage item, changes its nature and character very sharply in different areas. The division of the plan into eight primary Sections is as follows:

• Section 1.0.0 Baulkham Hills to Wisemans Ferry

• Section 2.0.0 Branch of the Great North Road between Abbotsford and Dural (the New Line)

• Section 3.0.0 Wisemans Ferry to Mount Manning Junction

• Section 4.0.0 Mount Manning to Wollombi

• Section 5.0.0 Wollombi to Maitland

• Section 6.0.0 Wollombi to Broke

• Section 7.0.0 Broke to Patricks Plains

• Section 8.0.0 Broke to Warkworth

• Section 1.0.0 Baulkham Hills to Wisemans Ferry

• Section 2.0.0 Branch of the Great North Road between Abbotsford and Dural (the New Line)

• Section 3.0.0 Wisemans Ferry to Mount Manning Junction

• Section 4.0.0 Mount Manning to Wollombi

• Section 5.0.0 Wollombi to Maitland

• Section 6.0.0 Wollombi to Broke

• Section 7.0.0 Broke to Patricks Plains

• Section 8.0.0 Broke to Warkworth

Great North Road Bridges

There are 8 major surviving bridges on the Great North Road from an original total of some 22. As they are the oldest known bridges on the Australian mainland, they form a group which are very significant for the development from simple stone concrete structure to the highly sophisticated forms and designs used north of the Hawkesbury River – Clares, Sampsons Pass and Circuit Flat Bridges. Two are quite close to Wisemans Ferry, one on the south side of the River just before the descent to Wisemans Ferry and the other on the north side just beyond the Ferry on Settlers Road where the Great North Road diverges to ascend Devines Hill.

Bridge 1: The present surfaced road diverges slightly from the line of the older road with the realignment bypassing a small stone bridge. This Bridge 1 is situated in a 43 metre section of abandoned formation just east of the present road. It is a small and simple structure with two parallel stone walls, spanned by 5 (originally 6) cross beams/log stringers with a span is 1.5 metres. The walls are Type 3a masonry and are up to 1.9 metres high. There are 7 courses in the southern wall and 8 in the northern one. The bridge is roughly 7 metres wide although the east end has been damaged. Percy Simpson referred to the completion of a bridge by No. 4 Iron Gang in January 1830, probably this one.

Bridge 3: As part of the present Settlers Road, it is now known as Thomas James Bridge. It is deceptive in that it appears to be of more recent construction. The timber deck is 7.7 metres wide and 5 metres long; in fact, it is set on concrete headstocks added into the tops of the older masonry abutments. The bridge was built during 1830 by No. 25 Road Party, under the supervision of Percy Simpson. Two massive masonry abutments for a conduit 16.3 metres long exist on the banks of the creek. The stone abutments are 6 metres high, battered and flared at the base. Wing walls extend from the abutments for 8 metres along the abutments to the north and for 30 metres to the south. The masonry is high class type 3b work. Very large stones are used in the foundation courses, with size decreasing towards the top. The bridge has two stone culverts within the uphill side of the abutments. They had flagged and walled races to direct flow from the side slopes into the main channel.

Bridge 1: The present surfaced road diverges slightly from the line of the older road with the realignment bypassing a small stone bridge. This Bridge 1 is situated in a 43 metre section of abandoned formation just east of the present road. It is a small and simple structure with two parallel stone walls, spanned by 5 (originally 6) cross beams/log stringers with a span is 1.5 metres. The walls are Type 3a masonry and are up to 1.9 metres high. There are 7 courses in the southern wall and 8 in the northern one. The bridge is roughly 7 metres wide although the east end has been damaged. Percy Simpson referred to the completion of a bridge by No. 4 Iron Gang in January 1830, probably this one.

Bridge 3: As part of the present Settlers Road, it is now known as Thomas James Bridge. It is deceptive in that it appears to be of more recent construction. The timber deck is 7.7 metres wide and 5 metres long; in fact, it is set on concrete headstocks added into the tops of the older masonry abutments. The bridge was built during 1830 by No. 25 Road Party, under the supervision of Percy Simpson. Two massive masonry abutments for a conduit 16.3 metres long exist on the banks of the creek. The stone abutments are 6 metres high, battered and flared at the base. Wing walls extend from the abutments for 8 metres along the abutments to the north and for 30 metres to the south. The masonry is high class type 3b work. Very large stones are used in the foundation courses, with size decreasing towards the top. The bridge has two stone culverts within the uphill side of the abutments. They had flagged and walled races to direct flow from the side slopes into the main channel.

Bridges further north

Bridge 4: Now known as Clare’s Bridge (Bridge 4), it is the largest and most ambitious bridge on the Great North Road. The bridge was constructed by Arnold Clare’s Bridge Party between January and September 1830. After completion, the gang was moved to Sampson’s Pass, presumably to construct Bridge 5, a small and simpler stone bridge. Clare’s Bridge has a unique two-span design with two large battered stone abutments, wing walls and a large central pier with V-shaped ends. The bridge is 3.3 metres high, 7.3 metres wide at the base and would have had an original deck of about 7.25 metres, supported by raking struts supported on stone corbels with projected from the pier and the abutments. The original masonry is fine ashlar (type 3b) work, carefully dressed, tooled and jointed. The approaches to the bridge were protected by stone masonry wing walls as much as 23 metres long on the SE side. The stone was quarried locally from a rock outcrop above the bridge, where jumper marks, split rock faces, wedge pits and shaped stone are evident. Previous damage and collapse of some masonry on the NE corner is further discussed in the Present Day folio, together with a description of the major repair work done in 1999.

Bridge 6: Known as Circuit Flat Bridge (Bridge 6), it is the most refined single span bridge design on the road, second only to Clare’s Bridge. It was clearly constructed by a bridge party experience in bridge building, strongly suggesting (Karskens’ thesis, 1.115) that the work was carried out by Arnold Clare’s Bridge Party, probably in 1831 after completing the bridge at Sampson’s Pass. Karskens comments that a suitable rock ford nearby could easily have been utilised to cross the Little Mogo Creek but that would have involved a slight deviation in the line of the road. This suggest that Simpson, like Mitchell, was interested in maintaining a straight road. The bridge is an impressive structure. It comprises two stone abutments, originally 14.6 metres in length, 8.5 metres wide, up to 2.7 metres high and with a span of 2.75 metres. Projecting buttresses flank each corner and there are seven stone corbels projecting from each abutment. These would have supported struts for the original decking. Masonry work is type 3b, random bonded and laid in regular courses with tight joints. The extensive flanking walls retain part of a coping course (or projecting string sourse) below a single course of capping stones. A large quarry, with partly worked stone blocks strewn about, occupies the top of a hill 1 km to the NW. The absence of documentary evidence about the construction phase is the result mainly of a lack of records for 1831 when the Roads and Bridges Department was transferred to the Surveyor General’s Department in that year. Again maintenance and repair work on the Circuit Flat Bridge are discussed in the Present Day folio.

Bridge 6: Known as Circuit Flat Bridge (Bridge 6), it is the most refined single span bridge design on the road, second only to Clare’s Bridge. It was clearly constructed by a bridge party experience in bridge building, strongly suggesting (Karskens’ thesis, 1.115) that the work was carried out by Arnold Clare’s Bridge Party, probably in 1831 after completing the bridge at Sampson’s Pass. Karskens comments that a suitable rock ford nearby could easily have been utilised to cross the Little Mogo Creek but that would have involved a slight deviation in the line of the road. This suggest that Simpson, like Mitchell, was interested in maintaining a straight road. The bridge is an impressive structure. It comprises two stone abutments, originally 14.6 metres in length, 8.5 metres wide, up to 2.7 metres high and with a span of 2.75 metres. Projecting buttresses flank each corner and there are seven stone corbels projecting from each abutment. These would have supported struts for the original decking. Masonry work is type 3b, random bonded and laid in regular courses with tight joints. The extensive flanking walls retain part of a coping course (or projecting string sourse) below a single course of capping stones. A large quarry, with partly worked stone blocks strewn about, occupies the top of a hill 1 km to the NW. The absence of documentary evidence about the construction phase is the result mainly of a lack of records for 1831 when the Roads and Bridges Department was transferred to the Surveyor General’s Department in that year. Again maintenance and repair work on the Circuit Flat Bridge are discussed in the Present Day folio.

Two Other Bridges, still in use

Thompson’s Bridge, Precinct 4.7.0, 1 km north of Murray’s Run, about 15 km south of Laguna: It is not certain whether this is an original structure but maybe a later replacement. The two-span timber trestle structure between the abutments is recent. The coursing of the abutments is uneven and unlevel with a batter achieved by recessing each course back about 5 cm. The stone walls on each side are coursed rubble work (type 2b), uncharacteristic of other work in this area.

Stone Bridge, Broke Road, Precinct 6.2.0, 21.5 km north of Wollombi: The origins of this bridge structure are presently unclear. It has a recent deck surmounting abutments of roughly squared, but otherwise unworked stone rubble. The masonry conforms with type 2b. It may be a later construction and further research is required.

Stone Bridge, Broke Road, Precinct 6.2.0, 21.5 km north of Wollombi: The origins of this bridge structure are presently unclear. It has a recent deck surmounting abutments of roughly squared, but otherwise unworked stone rubble. The masonry conforms with type 2b. It may be a later construction and further research is required.

Durable Pavement Preparation

In the sections on various aspect of provision of drainage for the Great North Road, the name of Macadam arises with mention of his major published work in 1824, noting his emphasis on the importance of drainage and the preparation of the road surface. Just four years later in June 1828, the Surveyor of Roads and Bridges, Edmund Lockyer, had set out detailed instructions to his Assistant Surveyors about the construction of drains and pavements, produced by the Government as Regulations for the Guidance and Conduct of the Road Department. We have given many examples of the way the Assistant Surveyors met Lockyer’s requirements on drains, culverts and races.

Let us now turn to what Lockyer further proposed for the preparation of pavements:

It is also necessary that Assistant Surveyors should be particular in the selection of the material for laying on the road. The best in the Colony is the whinstone or ironstone. There is also a hard blue coloured stone, which when broke to the size of one inch and a half to two inches is diameter and laid about six inches in depth and twenty one feet wide, with a coat of ironstone gravel over, first passing it through a screen to let the dirt pass through, makes an almost imperishable road. The latter material is easily found where an ironbark forest or scrub is seen or met with, there is certain to be found plenty of gravel. Regulations for Roads Department, Box 4/1984, CY905, Archives of NSW.

In some parts of the road line, it crossed considerable lengths where the surface was basically a rock platform. High spots were picked across the width of the road. Where the surface had cracks or gaps in it, those were filled with broken stone up to the level of the main surface. The photograph was taken near Sampson’s Pass where the road is badly eroded. It does show the rock platform which had been picked to a fairly level surface. Further along is evidence of the gravel and rock pieces used under the top surfacing. This area of road and those where filling had been completed up to about six inches below the final surface were covered with screened broken stone of about 1.5 to 2 inch gauge. The final addition was of a layer of crushed sandstone or screened gravel, raked over the broken stone layer. Gravel was not always available nearby on some sections of the road. However, at numbers of locations along the road, Lockyer’s advice was obviously being followed because excavations up to a metre in depth have been found, where there was suitable gravel to make the good road surface.

Again the Weekly and Monthly reports indicate how heavy this work was. Up to 15 men were involved in picking gravel, with the same number shovelling it into carts and four men spreading the gravel on the road surface. On Devine’s Hill Ascent, the No.3 Iron Gang carted 2,400 loads of gravel for spreading on that section of the road. Many of the weekly reports describe th tasks undertaken as breaking stone, picking gravel, shovelling gravel and raking gravel.

As Karskens notes, this aspect of the construction of the road is the most transient with more wear, damage and alteration than any other aspect. There are nevertheless small sections at various locations which appear to be original as a result of their strong resemblance to contemporary instructions and descriptions. The remnants occur exclusively in sections of the road, long abandoned, making them safe from extensive wear and maintenance operations.

One example given reads as follows:

The 2 km abandoned section scaling Devine’s Hill, has several slightly different examples of this type of broken stone pavement.

Near the base of the hill, at points where channels have been eroded across the roadway, the fill of large broken stones is exposed with the remnants of an upper layer of compacted stone, 75-100 mm gauge [3 to 4 inches]. Figure 8 [from her paper] shows also the remnant of a course of ironstone gravel, 12mm [half inch] gauge and finer, running continuously along the outer edge of the road. Another abandoned section at Mt McQuoid also illustrates a version of Lockyer’s instructions. Two sections of broken stone pavement are intact. The first is 6 to 7 metres wide and comprises compacted stone up to 100 mm [4 inches] in diameter. An earthen table drain on the east side reveals the thickness to be approximately 150 mm [6 inches].

On Devine’s Hill, there was a collapsed culvert and there was evidence of the structure of the pavement surface. Just back from the collapse, the surface layer showed the gravel (half inch and finer) which had been used. Closer to the hole and in the area eroded by water, the larger compacted stone remnants were present. In the picture, the gravel can be seen on the top left while the larger broken stones can be seen at bottom right. Wear and tear, erosion, damage and alteration have thus had a major impact on what can be viewed nearly one hundred and seventy years after the construction of the Great North Road.

Let us now turn to what Lockyer further proposed for the preparation of pavements:

It is also necessary that Assistant Surveyors should be particular in the selection of the material for laying on the road. The best in the Colony is the whinstone or ironstone. There is also a hard blue coloured stone, which when broke to the size of one inch and a half to two inches is diameter and laid about six inches in depth and twenty one feet wide, with a coat of ironstone gravel over, first passing it through a screen to let the dirt pass through, makes an almost imperishable road. The latter material is easily found where an ironbark forest or scrub is seen or met with, there is certain to be found plenty of gravel. Regulations for Roads Department, Box 4/1984, CY905, Archives of NSW.

In some parts of the road line, it crossed considerable lengths where the surface was basically a rock platform. High spots were picked across the width of the road. Where the surface had cracks or gaps in it, those were filled with broken stone up to the level of the main surface. The photograph was taken near Sampson’s Pass where the road is badly eroded. It does show the rock platform which had been picked to a fairly level surface. Further along is evidence of the gravel and rock pieces used under the top surfacing. This area of road and those where filling had been completed up to about six inches below the final surface were covered with screened broken stone of about 1.5 to 2 inch gauge. The final addition was of a layer of crushed sandstone or screened gravel, raked over the broken stone layer. Gravel was not always available nearby on some sections of the road. However, at numbers of locations along the road, Lockyer’s advice was obviously being followed because excavations up to a metre in depth have been found, where there was suitable gravel to make the good road surface.

Again the Weekly and Monthly reports indicate how heavy this work was. Up to 15 men were involved in picking gravel, with the same number shovelling it into carts and four men spreading the gravel on the road surface. On Devine’s Hill Ascent, the No.3 Iron Gang carted 2,400 loads of gravel for spreading on that section of the road. Many of the weekly reports describe th tasks undertaken as breaking stone, picking gravel, shovelling gravel and raking gravel.

As Karskens notes, this aspect of the construction of the road is the most transient with more wear, damage and alteration than any other aspect. There are nevertheless small sections at various locations which appear to be original as a result of their strong resemblance to contemporary instructions and descriptions. The remnants occur exclusively in sections of the road, long abandoned, making them safe from extensive wear and maintenance operations.

One example given reads as follows:

The 2 km abandoned section scaling Devine’s Hill, has several slightly different examples of this type of broken stone pavement.

Near the base of the hill, at points where channels have been eroded across the roadway, the fill of large broken stones is exposed with the remnants of an upper layer of compacted stone, 75-100 mm gauge [3 to 4 inches]. Figure 8 [from her paper] shows also the remnant of a course of ironstone gravel, 12mm [half inch] gauge and finer, running continuously along the outer edge of the road. Another abandoned section at Mt McQuoid also illustrates a version of Lockyer’s instructions. Two sections of broken stone pavement are intact. The first is 6 to 7 metres wide and comprises compacted stone up to 100 mm [4 inches] in diameter. An earthen table drain on the east side reveals the thickness to be approximately 150 mm [6 inches].

On Devine’s Hill, there was a collapsed culvert and there was evidence of the structure of the pavement surface. Just back from the collapse, the surface layer showed the gravel (half inch and finer) which had been used. Closer to the hole and in the area eroded by water, the larger compacted stone remnants were present. In the picture, the gravel can be seen on the top left while the larger broken stones can be seen at bottom right. Wear and tear, erosion, damage and alteration have thus had a major impact on what can be viewed nearly one hundred and seventy years after the construction of the Great North Road.